why choose our High Power laser cutter?

Increased Cutting Speed

15000-40000W Laser Power Optional, able to cut through thicker metal sheets at a faster rate

of up to 65m/min (213′/min), enabling you to achieve higher production efficiency and output

in a shorter time

High Positioning Speed

Whole machine uses industry-leading servo motors, providing high positioning speed of 126m/min (413′/min) and acceleration of 2G, achieving faster movement and improved working efficiency

Increased Cutting Quality

Our machine offers precise cuts and high-quality results. The cutting surface is smooth,

flat, and without obvious burrs, reducing the need for post-processing

Certification

This super high power laser cutter is certified with CE, FDA, and ISO, ensuring that it meets

the highest quality and safety standards.

Intelligent Maintenance

Our machine is maintenance-free thanks to its automatic lubrication and intelligent air pressure monitoring system, it always operates at its best, you can focus on your opeations and business instead of stopping to maintain

Safety

With the intelligent collision detection system, the machine automatically stops if any potential collisions occur. The enclosed structure prevents hazardous debris, fumes, and radiation from escaping, thus protecting the safety of workers.

Product Features

Advanced Fiber Laser Source

- Laser Power: 15000-40000W Optional, High-power Output, Fast and Efficient Cutting

- Brand: IPG/MAX/RAYCUS/GLORYSTAR Optionl

- Concentrated Energy, Good Quality Laser Beam, ensuring precise and smooth cutting rusults

- High photoelectric conversion rate of up to 30%, efficiently converting electrical energy into laser energy, saving up to 50% in energy consumption, lowering operational costs

- Maintenance-free, up to 100,000 hours of service life

Auto-Focus Cutting Head

- Automatic focus ensures optimal cutting position for different materials and thicknesses, achieving high efficiency and cutting quality without manual intervention

- Collision Protection, Durable, Long Service Life and Low Maintenance Costs

FSCUT Bus System

- Super Piercing Function:

–Multiple piercing solutions for metal sheet of different thickness, especially for thicker materials or high-volume cutting tasks

–Quick penetration through various materials, perforation efficiency increased by 45%

–Piercing slags removal, improving cutting quality and reducing secondary processing - Find Edge: up to 500mm/s high speed with precision find sheet edge, also provie optional find edge patterns to meet your production needs.

- High-Precision Cutting:Focus correction, ensuring the laser beam at the right position and size, improving the cutting quality and precision

- Cost-saver:

–Capture remnant sheet to reuse the material, reduced material waste

–Digital monitoring with Laser Cloud and MES access prevents malfunctions, reduces downtime, and lowers maintenance costs -

User-friendly: Easy operation with guided and visualized interface

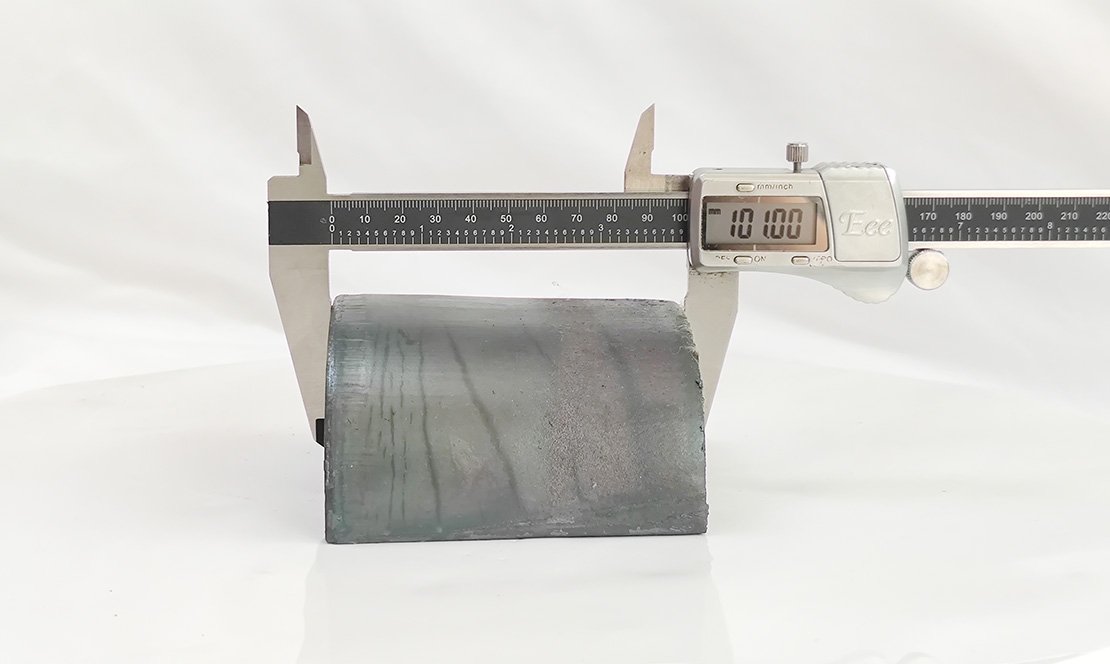

Patent Hollow Double Bed Frame

- Hollow bed design: free of connections inside, minimizes heat transfer and eliminates any risk of compromising your cutting accuracy.

- Revolutionary double bed frame: The inner and outer beds are designed to independently bear weight, providing unmatched weight capacity of up to 24 tons. The bed won’t deform even with prolonged use, ensuring long-lasting performance and reliable use for decades to come.

Automatic Zoning Dust Removal System

Our machine features 30 dust removal zones, which work seamlessly to remove dust and smoke, so that it maintain a dust-free, clean and safe work environment

As an added benefit, it protects the machine components from dust pollution, extending the machine lifetime and ensuring optimal cutting conditions every time

Full Servo Control System

Experience unmatched cutting precision with our innovative full servo control system. This advanced technology enables digital positioning, ensuring unparalleled accuracy that eliminates the risk of costly errors and delivers outstanding results every time.

But that’s not all. Our system also boosts the traction force of the worktable, providing maximum stability and minimal downtime for increased productivity.

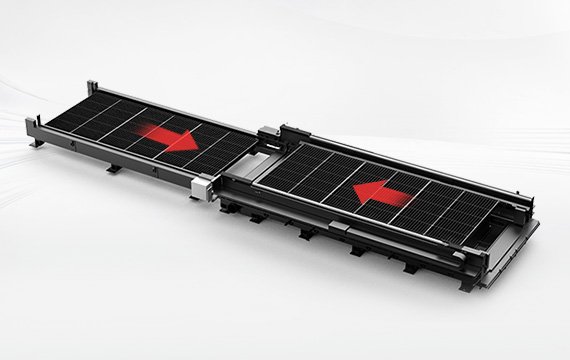

Fast Exchange Worktable

Thanks to the automatic exchange table, you can load and unload materials while cutting. And the exchange is fast, it only takes 20s to complete one, help to accelerate the material flow during loading and unloading, save time and increase efficiency.

It is worth noting that the upper and the lower table is driven by different servo motors, the cutting precision of the upper worktable will not be affected by any vibrations caused by loading on the lower worktable, and vice versa, ensuring the highest level of precision in all your cutting operations.

Industrial Air Conditioning System

Capable of controlling the temperature and humidity inside the machine, there is no need to equip an air-conditioned room for the machine.

This achieves stable performance even during prolonged use and protects the service life of the machine and electrical components

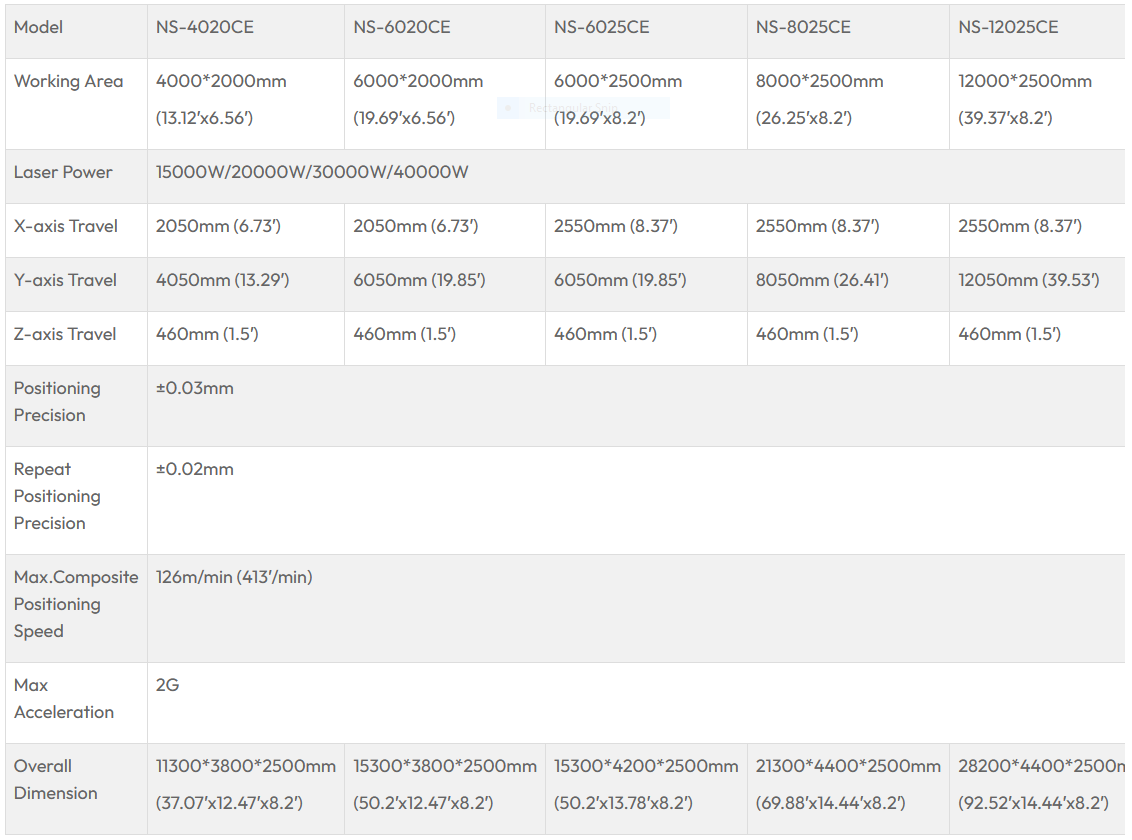

Technical Parameter

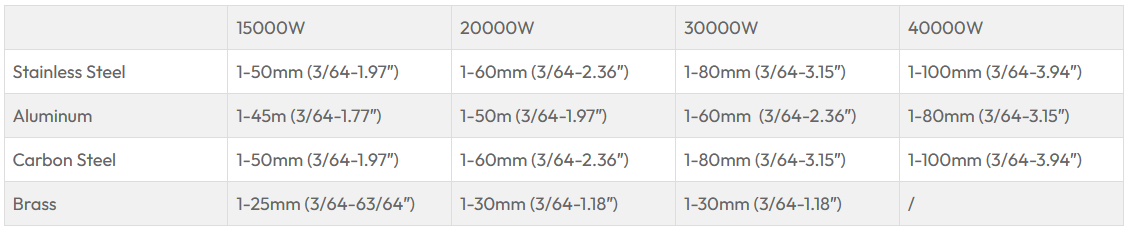

Cutting Capacity

Cutting Samples

Contact

For any kind of query, contact us with the details below.

- + 91 96777 99924 , +91 96777 99958 , +91 95359 95573

- sales@keesstech.com

- No.2, Maruthaiyah Nagar,Kattabomman Street,Ganapathy,Coimbatore - 641006

Contact us for cost-effective laser solutions!